Since the introduction of OBD II and leading up to modern Hybrids and EVs, computers and software in cars have been expanding at an exponential rate.In-car software is becoming one of the leading needs for service, and updating

software may be the only way to fix some of these issues:

* Drivability

* Fuel Efficiency

* Power Loss

* Fault Codes

* Durability of Mechanical Parts

The Programming and Coding function is used to re-flash the vehicle control modules, it allows you to update the computer software on the vehicle to the latest version, as well as to reprogram adaptive data for certain components after making repairs or replacements.

NOTE: The Autel OBD2 Scanner programming function can only be applied through connection with the J2534 programming device, which serves as a PassThru interface to establish communication with and transfer data to the vehicle’s ECU.

Available programming or coding operations vary by the test vehicle, and only the available operations display in the menu.

There are two general types of programming operations:

A. Coding – also known as Teach-in Program, Component Adaptation or something similar, is used to reprogram adaptive data for vehicle control modules after repairs or replacements of vehicle parts.

B. Reprogramming Operations – downloads new version of software subscription from the on-line server database through internet access (this procedure is done automatically when the MaxiSys display tablet is connected to the internet, so there is no need to check for software subscriptions yourself), and reprograms the newest software version to the vehicle’s ECU.

NOTE: Ensure that the display tablet is connected to the Internet before applying the ECU Programmin function, so that the display tablet is able to obtain access to the manufacturer’s server for update service.

Selecting the Programming or Coding function opens a menu of operation options that varies by make and model. Selecting a menu option either shows a programming interface or opens another menu of additional choices. Follow on-screen instructions while performing the programming or coding operations.

How and what information is presented on the screen varies according to the type of operation being performed.

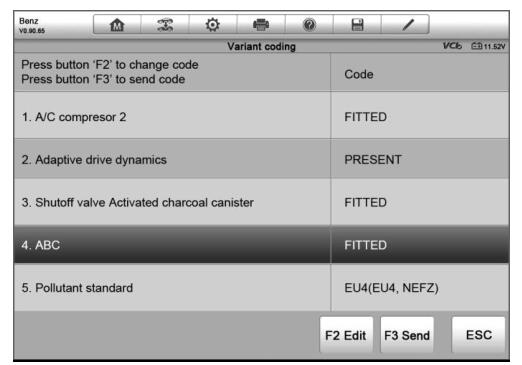

Variant Coding

The main section of the Maxisys Elite Variant Coding screen displays a list of vehicle components and the coding information which mainly consists of three parts:

1. The top line on the list displays the instruction of how to use the functional button at the lower right corner of the screen to manipulate the coding operations.

2. The second part under the top line of the list displays all available systems for coding on the left side, and the coding data or value on the right side.

3. The bottom line of the main section displays the functional buttons which allow you to manipulate the operation.

Check the vehicle condition and the coding information carefully, and use the functional button to edit Codes for the corresponding components, tap Send when you finish edit for all the items. When the operation is done, an execution status message such as Completed, Finished or Successful, may display.Tap the ESC button to exit the function.

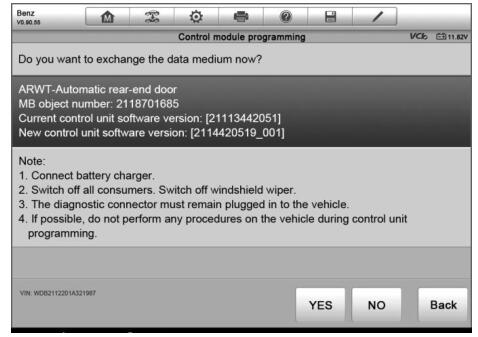

Reprogramming Operation

Typical reprogramming operations require you to input and validate VIN number first. Tap the input box and enter the correct number, the programming interface then displays.

The main section of the reprogramming interface provides you certain hardware version, and current software versions’ information, as well as the information of the newest software versions to be programmed to the control units.

Throughout the programming procedure, a series of on-screen operational instructions will display to guide you through Auto diagnostic tool. Carefully read the on-screen information and follow the instruction to execute the programming procedure.

IMPORATANT: When reprogramming onboard, always make sure the vehicle battery is fully charged and in good working condition. During reprogramming there is a risk of having the operation failure if voltage falls below the proper operation voltage. Sometimes a failed operation can be recovered, but there is a chance that failed reprogramming could ruin the control module. We recommend connecting an external battery charger to the vehicle to ensure a successful operation.

Occasionally a flash update procedure may not complete properly. Common causes of flash errors include poor cable connections between the display tablet, VCI, and vehicle, turning off the vehicle ignition switch before the flash procedure is complete, or low vehicle battery voltage.

If the process crashes, recheck all the cable connections to assure good communications and reinitialize the flash procedure. The programming procedure will automatically repeat if the previous operation does not succeed.